The Ultimate Flat Roof Calculator Guide

- Vijaykumar Patel

- Jan 30, 2024

- 12 min read

Table of Contents (Click on the calculator topic to jump to that section)

Introduction

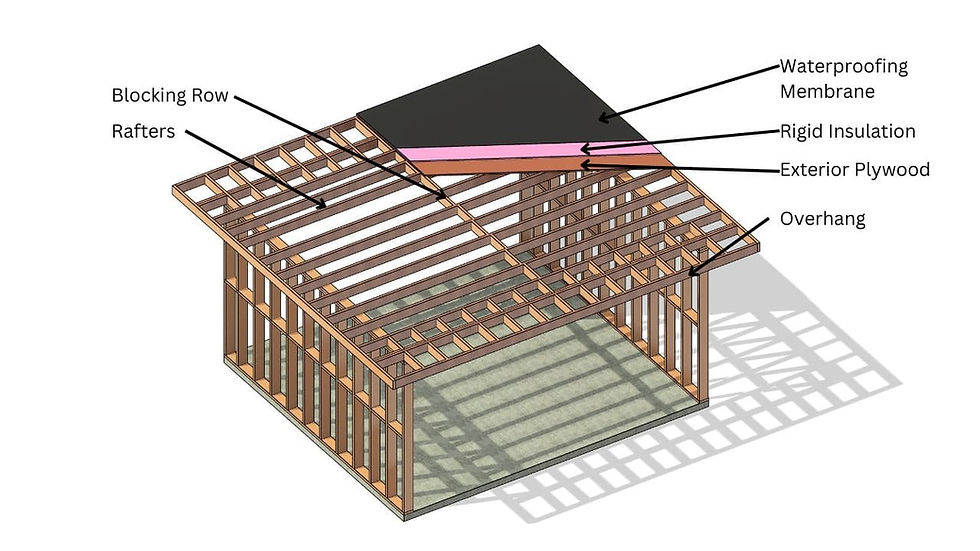

We'll dissect every roofing system layer in this tutorial, from the basic framework of rafters and built-up beams to the last touches of paint and fascia boards. We've also included a useful calculator to help you estimate material requirements and avoid wastage during the construction process.

It might be difficult to navigate the complexities of roof construction, but our step-by-step guide tries to make things easier. Whether you're an experienced contractor or a do-it-yourselfer, this guide will help you choose the best kind of roof, comprehend the importance of each layer, and make the most use of our waste calculator.

Come along on this tour through the many layers of a well-made roof, and at the end, you'll have the information and resources you need to decide on your roofing job. Now let's get started!

#1 Choosing Roof Types

Any building project must carefully consider the sort of roof to use, and when it comes to flat roofs, two common approaches stand out: stick-framed flat roofs and truss flat roofs. Every strategy offers benefits and things to take into account that affect the roof's overall performance, cost, and design.

Truss Flat Roof

Structural Simplicity: Truss flat roofs are renowned for having a straightforward structure. Typically constructed of steel or wood, engineered trusses offer a reliable framework with prefabricated parts that expedite the building process.

Cost-Efficiency: Using prefabricated trusses frequently results in lower costs. Shorter construction timetables and lower labor costs might result from manufacturing and installation efficiency.

Design Flexibility: Trusses support a variety of architectural styles and offer a range of design options. Because of their adaptability, truss flat roofs can be used in both commercial and residential settings.

Load Distribution: The uniform load distribution of beams guarantees a sturdy structure that can withstand the weight of snow, roofing materials, and other environmental elements.

Stick Framing Flat Roof

Adaptability and Customization: Stick framing, sometimes referred to as conventional framing, provides a great degree of adaptability. Builders can modify the design to satisfy particular architectural specifications and incorporate special features.

On-Site Adjustments: Stick framing allows for on-site adjustments, making it a good choice when dealing with anomalies in the construction site or when modifications are needed throughout the building process.

Accessibility: Stick framing is suitable for a variety of construction projects because of the readily available materials and the ease of the framing process. Transport expenses can be kept to a minimum by using locally available resources.

Maintenance and Repair: Stick framing has advantages in terms of maintenance and repairs. It is possible to fix or replace individual parts without damaging the structure as a whole.

When deciding between a stick-framed flat roof and a truss flat roof, it's critical to take your project's particular needs into account. This includes things like construction ease, price, and design preferences. Since both approaches have a track record of success, the choice ultimately comes down to which best suits your particular requirements and priorities.

#2 Rafters

If you are planning to install a Truss Roof, then you can skip this step.

The weight of the roof covering is supported by the walls or beams that support it, which is distributed by the rafters, and the slanted roof structural elements. These sloping beams extend from the ridge, the highest point where two roof slopes converge, to the eave, the lower edge of the roof that overhangs the walls. Rafters distribute the weight of the insulation, roof covering, and other loads and act as the structural support system of the roof.

Rafter spacing

One of the most important factors in determining the roof's overall strength and stability is the space between the rafters. The kind of roofing material, regional building rules, and the particular design specifications of the structure all have an impact on the spacing. The typical rafter spacing is 16 inches to 24 inches in the center, with many residential buildings using 16 inches as the standard. For any particular project, you must, however, refer to the engineering specifications and local building rules to ascertain the proper spacing.

Overhang

The roof's extension past the outside walls is known as the overhang, and it has both practical and decorative uses. In terms of functionality, it helps shield the walls from the sun and rain, avoiding water damage and offering shade. It can visually improve a building's curb appeal and add to its architectural style.

Although the overhang's size is a matter of design, combining functionality and beauty in equal measure is crucial. Although a longer overhang offers greater shelter and shade, it can also raise the cost of materials and complicate installation. On the other hand, a smaller overhang could be less expensive but might provide less protection.

Rafter Length = Building Width (Rafters are parallel) + Both Side OverhangNumber of Rafters Required = Building Length / Rafter Spacing

Total Price = Total Rafters Required x Each Rafters PriceWhere,

Building Length - Rafters are Perpendicular Direction

#3 Built-up Beam

The built-up beam is essential for providing structural stability and support while building a flat roof. In contrast to conventionally pitched roofs, flat roofs need a sturdy foundation to disperse weight uniformly and endure different weather scenarios.

A Built-Up Beam: What Is It?

A built-up beam is a structural component made of materials layered and piled deliberately to create a strong and dependable support structure. These beams are intended to support the weight of the roof in the case of flat roofs and transfer it to the walls or columns of the building. To form a composite structure with increased strength, various elements, such as steel, wood, or engineered timber, are combined during the building of a built-up beam.

Installation-Related Considerations:

Professional Consultation: To ascertain the particular needs of your flat roof and design a suitable built-up beam, it is advisable to confer with a structural engineer or other competent professional.

Weatherproofing: Appropriate weatherproofing techniques are crucial due to the horizontal orientation of flat roofs. The top layer of the built-up beam should be made to withstand weathering and water intrusion.

Code Compliance: To ensure safety and structural integrity, make sure the built-up beam's construction complies with all applicable local building rules and regulations.

Example

For the flat roof of the garage building, we need three 2x8s that run parallel to the 12-foot building. Board Size As Per Manufacture 8 Feet / 9 Feet or 10 Feet. To clarify, we multiply by 3 because there are 3 layers in total.

Number of Boards Required = {Building Length (12Feet) / Board Size As Per Manufacture (8 Feet)} x 3

Total Price = Total Boards Required x Each Board Price#4 Blocking Between Rafters

Blocking between rafters has several functions, all of which are essential to the roof's long-term functionality. By serving as lateral supports, these blocks keep the rafters from twisting or warping under the weight of the roof as well as outside factors like wind and snow. Blocking improves the overall strength and durability of the roofing structure by more evenly spreading the load.

Blocking also helps to avoid any problems like ceiling drooping or cracking by providing a stable and level surface for the roofing system's later layers. It also makes it easier to install insulation, sheathing, and other components correctly, which is crucial for producing a roofing assembly that is both weathertight and energy-efficient.

Resources

Plywood, oriented strand board, and dimensional lumber are often used materials for blocking (OSB). The selection of material is frequently influenced by variables such as financial limitations, structural specifications, and local construction codes.

Example

For the flat roof of the Pool House building, we need two 2x10s that run parallel to the 20-foot building. Board Size As Per Manufacture 8 Feet / 9 Feet or 10 Feet. To clarify, we multiply by 2 because there are 2 layers in total.

Number of Boards Required = Building Length (20Feet) / Board Size As Per Manufacture (8 Feet)

Total Price = Total Boards Required x Each Board Price#5 Layer 1 - Waterproof Finish

One of the most important layers in building a robust roof is waterproofing. A key component in stopping water intrusion and safeguarding the supporting structure is the water-resistant membrane. The main characteristics and uses of the many kinds of waterproofing membranes are outlined here.

Waterproofing Membrane Comparison Table:

Membrane Type | Material Composition | Application | Advantages | Disadvantages |

Bituminous Membrane | Asphalt or coal tar impregnated with fabric | Flat or low-slope roofs | - Excellent waterproofing - UV resistance | - Heavy and difficult to handle - Limited flexibility |

EPDM (Ethylene Propylene Diene Monomer) | Synthetic rubber | Flat or low-slope roofs | - High flexibility - Easy installation | - Susceptible to punctures - Limited color options |

TPO (Thermoplastic Olefin) | Single-ply reflective roofing membrane | Flat or low-slope roofs | - Energy-efficient - Resistant to algae and bacteria | - Limited heat resistance - Prone to punctures in certain conditions |

PVC (Polyvinyl Chloride) | Thermoplastic polymer | Flat or low-slope roofs | - Chemical resistance - Durability | - Limited flexibility in cold temperatures - Environmental concerns with manufacturing |

Liquid Applied Membrane | Liquid polymer or bitumen-based | Irregular or complex roof shapes | - Seamless application - Adheres to various surfaces | - Requires skilled labor for application - Cure time may be longer |

Formula

Sqft Waterproof Finish Required = Sqft of Roof Area

Total Price = Total sqft material Required x material sqft PriceWhere

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

#6 Layer 2 - Rigid Insulation

To improve your roofing system's thermal performance and energy efficiency, rigid insulation is essential. This layer, which is positioned directly below the waterproof finish, serves as a barrier to heat transfer and efficiently controls the temperature in your living or working area.

Rigid insulation, which is made of sturdy materials like foam boards or panels, offers a continuous layer of defense, reducing heat loss in the winter and limiting heat gain in the summer. This helps save energy use and utility expenses in addition to creating a more comfortable interior atmosphere.

Formula

Total number of Sheets Required = Total Roof Area / Area of Each Sheet

Total Price = Total number of Sheets Required x Each Sheet PriceWhere

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

Coverage per Sheet: The area covered by one sheet depends on size. For example 32 sqft for (8 feet x 4 feet)

Make sure to determine how many layers you need. For example, if you need R20ci but can only find R10ci sheets in the market, you'll need to order double sheets.

#7 Layer 3 - Exterior Sheathing

When it comes to protecting your roof from the elements and bolstering its structural integrity, outside sheathing is essential. This layer provides a strong base for the layers that follow, making it the structural core of the roofing system.

Importance of Exterior Sheathing

Structural Support: Exterior sheathing for structural support lies in its ability to give the roof covering a solid surface and sustain the complete roofing structure.

Wind Resistance: It strengthens the roof's resistance to wind, serving as a barrier against outside influences that could otherwise cause it to fail.

Moisture Barrier: By serving as a layer that is resistant to moisture, external sheathing lowers the possibility of water seeping in and causing rot, mold, and structural damage.

Formula

Total number of Sheets Required = Total Roof Area / Area of Each Sheet

Total Price = Total number of Sheets Required x Each Sheet PriceWhere

Number of Sheets: This is the total number of sheets required.

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

Coverage per Sheet: The area covered by one sheet depends on the size. For example 32 sqft for (8 feet x 4 feet)

#8 Layer 4 - Fascia Board

A well-built roofing system must include the fascia board, which has both functional and decorative uses. The fascia board, which is positioned at the bottom edge of the roof, is crucial in supporting the bottom row of roof tiles or shingles and giving the structure a polished appearance.

Materials and Upkeep

Composite, wood, vinyl, and aluminum are frequently used to make fascia boards. Aesthetic preferences, financial constraints, and climate all influence the choice of material. Given that the fascia board is exposed to the outdoors and sometimes dampness, regular care is necessary to guarantee that it stays in ideal shape.

Formula

Number of Fascia Board = [{(2) Buildin Length + Both Side Overhang} + {(2) Buildin Width + Both Side Overhang}] / Board Length As Per ManufactureWhere

Number of Fascia Board: This is the total number of board

Building Length: The Rafter's Perpendicular side is considered as building length

Board Length As Per Manufacture: Find online in-store or use a typical size 8 ft

#9 Layer 5 - Soffit

A well-designed roofing system must include the soffit, which is sometimes disregarded despite being essential to both functioning and aesthetics. The soffit, which is located beneath the roof overhang, fulfills several functions and enhances the overall aesthetics and structural integrity of your building.

Important Roles

Ventilation: Soffits give your attic space the vital airflow it needs to control humidity and temperature. Enough ventilation keeps moisture from accumulating, which lowers the possibility of mold growth and structural damage.

Aesthetic Appeal: Soffits improve your home's appearance in addition to its performance. They provide a smooth, finished look to the rooftop while hiding the rafter beams. Because soffits are available in a variety of materials and styles, homeowners can tailor the appearance to match their preferred architectural style.

Formula

Required Soffit Area= [{Building Length + Both Side Overhang} × Soffit Width] + [{Building Width + Both Side Overhang} × Soffit Width]

Total Price = Price Per Soffit Area x Total Required SoffitsWhere

Building Length: The Rafter's Perpendicular side is considered as building length

Soffit Width: Typical size is 6 inches to as wide as 24 inches or more.

#10 Layer 6 - Vapour barrier

The vapour barrier is essential to the complex construction of a roofing system because it keeps the balance between moisture control and insulation. This layer, which is important but frequently disregarded, acts as a barrier against any damage that could result from moisture buildup inside the roof structure.

A Vapour Barrier: What Is It?

A vapour barrier is a material that is specifically made to make it difficult for water vapor to travel through the different layers of a building envelope and into the insulation and other structural elements. The vapour barrier, which is installed on the warm side of the insulation and usually faces the interior of the building, helps regulate condensation and reduces the possibility of mold, rot, and structural damage.

Formula

Total Required Rolls = (Roof Area / Coverd Area Per Roll)

Total Price = Price Per Roll x Total Required RollsWhere,

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

Covered Per Roll = As per Manufacture

#11 Layer 7 - Batt Insulation

Batt insulation is a popular choice for insulation when it comes to building a comfortable and energy-efficient living area. Insulation is important. Rectangular panels that are pre-cut from a variety of materials, like mineral wool, and fiberglass, or natural fibers like cotton, make up batt insulation.

Batt insulation is primarily used to control indoor temperatures by obstructing the flow of heat from a building's outside to its inside. These insulation panels, when installed tightly between the rafters, studs, and joists, reduce heat gain and loss by forming a thermal barrier. This greatly reduces energy consumption in addition to assisting in keeping the inside temperature steady and comfortable.

Formula

Total Required Bags = (Roof Area / Coverd Area Per Bags)

Total Price = Price Per Bag x Total Required BagsWhere,

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

Covered Per Bag = As per Manufacture

#12 Layer 8 - Gypsum Board

Gypsum board is one of the most important parts of a well-built roof's layered structure. Gypsum board, sometimes referred to as sheetrock or drywall, is a crucial component in improving the overall integrity of the roofing system since it serves as a protective barrier and adds extra structural support.

Formula

Total Required Sheets = (Roof Area / Coverd Area Per Sheet)

Total Price = Price Per Sheet x Total Required SheetsWhere,

Roof Area = (Building Length + Both Side Overhang) x (Building Width + Both Side Overhang)

Covered Per Sheet = 32 sqft (4 feet x 8 feet)

#13 Layer 9 - Paint

Although paint is frequently thought of as the finishing touch in a building project, its importance in a roofing system extends beyond appearance. The proper paint can give an extra layer of protection against inclement weather while extending the lifespan and durability of your roof.

Formula

Total Required Gallon = (Ceiling Area / Coverd Area Per Gallon)

Total Price = Price Per Gallon x Total Required Gallonwhere,

Ceiling Area = (Building Length x Building Width)

Covered Per Gallon = 350 sqft per 1 Gallon per coat (We require 2 Coat which can paint 175sqft)

Wastage For Calculator

Choosing the appropriate materials is only one aspect of building efficiency; another is reducing waste generated during the process. Waste can harm the environment and your budget, whether it results from imprecise measures or unanticipated circumstances. This section will discuss the significance of reducing waste and present a useful calculator to assist you in more precisely estimating material requirements.

Taking into account variables including the kind of materials used, the project's complexity, and any measurement errors is essential to comprehending and controlling waste. Using this waste calculator in your planning will help you make the most use of your resources, cut down on wasteful spending, and support sustainable building methods.

Conclusion

To sum up, building a sturdy and effective roof requires careful consideration of multiple layers, each of which is essential to the structure's overall performance. Every layer of your roof, from the structural components like rafters and built-up beams to the finishing details like paint and fascia boards, adds to its strength, insulation, and weatherproofing.

You now have a thorough understanding of the fundamental levels of roof building from our tutorial, enabling you to make wise selections for your project. This information will help you navigate the complexities of the procedure, whether you are starting from scratch or replacing your roof.

FAQs

Why is it crucial to comprehend a roofing system's various layers?

It is essential to comprehend the different levels of a roofing system to guarantee the strength, insulation, and lifespan of your roof. Every layer has a distinct function in shielding your house from the weather.

How can I select the best kind of roof for my project?

The sort of roof you choose will rely on some things, such as your climate, financial situation, and personal style preferences.

What is the function of a roofing system's vapour barrier?

It is essential to have a vapour barrier to keep moisture out of the roof structure.

How do I calculate the amount of material I'll need and reduce waste when building a roof?

As we cover in the "Wastage For Calculator" section, our waste calculator will help you estimate the materials you'll need and cut down on waste.

I'm a do-it-yourself enthusiast; should I hire someone to do the roofing work?

While some parts could be do-it-yourself chores, roofing jobs frequently call for specialized knowledge. Before making a decision, assess your abilities and the project's complexity.

*Please note that the information shared in our blog is for educational purposes only, and we do not assume any liability for the actions or decisions made based on this information.

Comentarios